crushing machine jawbreaker jaw crusher

Industrial Solutions Jaw crushers - ThyssenKrupp

thyssenkrupp jaw crushers are mainly designed to crush medium-hard to very hard materials. Over a hundred years of experience in manufacturing jaw crushers.

More

J50 Jaw Crusher - McCloskey International

With 1270mm (50”) x 735mm (29”) single toggle jaw (the widest jaw in its class), the J50 places McCloskey International at the fore of portable crushing machinery. J50 Jaw Crusher Maximum productivity is delivered through the

More

Jaw Crushers - Astec

Jaw Crushers. Available in a variety of sizes and configurations, the Hydra-Jaw® crusher, Pioneer® jaw crusher and Iron Giant jaw crushers deliver high-capacity crushing and reliable performance for increased operational productivity and profitability.

More

Jaw Crushers Heavy Duty Terex Finlay

The Finlay® J-960 is the most compact tracked jaw crusher in the Terex® Finlay range. This aggressive and versatile crusher is ideal for small scale on-site crushing of aggregates and

More

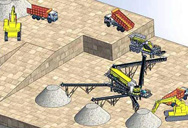

Jaw Crushers MAGNA Large-Scale Quarrying Machinery

At MAGNA, our jaw crushers are engineered to deliver powerful, reliable, and efficient crushing performance for a range of applications, including quarrying, demolition, recycling, and mining.

More

Jaw Crushers – MEKA

Jaw crushers are used as the primary crushers in the first stage of a crushing process for the breaking of large-sized rocks, while jaw crushers with smaller mouth openings are used to break smaller ores into finer sizes. Two basic jaw

More

The Ultimate Guide to Jaw Crushing Machines: Types More

2023年2月21日 There are three main types of jaw crushers: single-toggle jaw crushers, double-toggle jaw crushers, and hydraulic jaw crushers. Each type has its own unique features and benefits, making it important to choose the right one for your specific needs.

More

Industrial Solutions Jaw crushers - ThyssenKrupp

Solutions has in its range two types of jaw crusher, ... on our services and you can count on a wealth of experience and constant innovative drive. As a leading manufacturer of machines and plants for the aggregates and mining industry, ... • Enhanced crushing jaw profile and crushing chamber geometry, optimized

More

Stone Crusher Manufacturing Equipment in Kenya

Name:Jaw Crusher Model:PE400x600 With 30KW Motor Capacity:16-60 T/H Application:Used in the crushing... KSh 1,864,000 Reliable and New Ball Mill Machine

More

Mastering Jaw Crusher Plates: A Comprehensive Guide

2023年2月21日 Jaw crushers are popular crushing equipment used for reducing the size of rocks and ores. The crushing process is achieved through the use of a jaw crusher plate, which is the fixed or movable component of

More

Tiger Jaw crushing machines - Maxtec

TIGER MOBY jaw crushing machines MOBY: highly-effective, easy-to-maintain jaw crushers. The machines of this product line are built following a double logic: MULTI-FUNCTIONALITY: this allows all MAXTEC treatment plants to be installed on the same machine body (for example, in case you need to replace the jaw crusher with the impact mill). INTERCHANGEABILITY: to

More

Jaw Crushers Heavy Duty Terex Finlay

Finlay® tracked Mobile Jaw Crushers are renown for their capabilities in the reduction and sizing of aggregates for construction materials and also recycling construction waste. The Finlay range of Jaw Crushers are designed to meet the toughest demands of primary crushing applications with their impressive power, reliability and proven performance.

More

Types of Crushers: What You Need to Know Machinery Partner

ARK 2416 jaw crusher in action Gyratory crushers. Run of mine material is transferred into a gyratory crusher’s upper-level hopper. The walls of the gyratory crusher’s hopper are lined with “V-shaped” pieces, the mantle and the concave, like a jaw crusher but shaped like a cone.

More

How does a Rock Crusher Work - Jaw Crusher - 911Metallurgist

2021年11月22日 By inserting shims above the toggle block, the crushing stroke can be adjusted. Insertion of shims behind the toggle block adjusts the size of the discharge opening. Parallel alignment is assured and unnecessary strain in the crushing machine is avoided. The pitman in any jaw crusher is essentially a tension member.

More

Choosing the Right Jaw Crusher Size and Capacity for Optimal

2023年2月28日 Maximizing crusher performance and productivity requires selecting the right jaw crusher size and capacity. Learn how to determine the optimal size and capacity for your application, and discover the benefits of choosing the right equipment. Our expert guide provides valuable insights and recommendations for achieving the best possible results.

More

Primary Crusher vs. Secondary Crusher: Understanding Their

2023年2月28日 The primary crusher is the first stage in the crushing process, while the secondary crusher is the second stage. Function and Operation: The function of the primary crusher is to break down the larger rocks and stones into manageable sizes, while the function of the secondary crusher is to further refine these sizes into the desired product.

More

Crushing Equipment Supplies Jaw Crusher, Impact Crusher, Cone Crusher

Our extensive product range includes Jaw crusher, impact crusher, cone crusher, compound crusher, roll crusher, heavy hammer crusher, and hammer crusher. They differ in the feeding size, raw materials dealing with, working principle, processing capacity, and play in a different stage of the crushing process.

More

Jaw Plates: Everything You Should Know Crusher

2023年2月16日 If you’re in the market for a jaw crusher, you’re likely to come across the term “jaw plates.” Jaw plates are an essential component of the jaw crusher that is responsible for crushing the material. In this article, we’ll

More

Types of Crushers: Choosing the Right One for Each Stage

2024年7月17日 Jaw Crusher. Jaw crushers use the compressive and bending action of a fixed jaw plate and a movable jaw plate to crush materials of various hardnesses. ... Fine crushing: Utilize sand making machines, roll crushers, fine crushers or compound crushers in tertiary crushing to produce fine sand or powder. 4.

More

Primary Jaw Crusher – Everything You Need to Know

2023年2月28日 Learn everything you need to know about primary jaw crushers in this comprehensive guide. Discover how they work, their applications, and where to buy them from reputable sources. Whether you're in the mining or

More

RHINO series Primary Jaw Crusher - CPC Crushing and Screening Equipment

CPC 3624 Rhino Primary Jaw Crusher – Upto 150 TPH Capacity. The Rhino Series Primary Jaw Crusher offers Huge Advancements over traditional Single Toggle Machines. It requires minimum maintenance and is Perfect for “Jaw-Jaw combination” crushing. This machine incorporates modern technologies to give unbeatable economy and a long service life.

More

Dynamics Analysis and Chaos Identification of Compound Pendulum Jaw ...

2022年11月24日 A dynamic model of the working mechanism of a compound pendulum jaw crusher with clearance is established by the Lagrange multiplier method (LMD) based on the L-N contact force model and modified Coulomb friction force model. The correctness of the dynamic model is verified by MATLAB and Adams comparison simulation, and the best selection range

More

What Are Jaw Crushers and How Do They Work? - Oreflow

The size of a jaw crusher is measured by the top opening of the crushing chamber. For example, a 48” x 42” jaw crusher measures 48” from one crushing jaw to another and is 42” across the width of the two crushers. The primary applications for using jaw crushers are: Crushing different kinds of ore; Reducing building rubble to pieces

More

Crushing Equipment Superior Industries U.S. Manufacturer

Liberty® Jaw Crusher. Primary. Maximum Feed Size 47″ (1,194mm) Maximum Reduction Ratio 6:1. Maximum Production Rate ... Connect with one of our crushing experts and find the right machine. See our privacy policy. SUPERIOR INDUSTRIES, INC. Rock Face to Load Out ...

More

Stone Crusher - Rock Crushing Machine

As the material is fed into the crusher, the movable jaw presses it against the fixed jaw, crushing it into smaller pieces. impact crushers work by using high-speed rotors that throw stones against hard surfaces, creating fractures upon impact. cone crushers break down stones by squeezing them between a rotating mantle and a stationary concave, while hammer

More

La guía definitiva sobre trituradoras de mandíbulas primarias: qué ...

2023年2月28日 Aprenda todo lo que necesita saber sobre las trituradoras de mandíbulas primarias en esta guía completa. Descubra cómo funcionan, sus aplicaciones y dónde comprarlos de fuentes acreditadas. Ya sea que trabaje en la industria minera o de la construcción, esta guía lo ayudará a tomar una decisión informada cuando se trata de seleccionar la trituradora de

More

Crushers|Furukawa Industrial Machinery Systems Co., Ltd

This Brake Jaw Crusher is an energy-saving double toggle crusher with a reduced machine height. ・Tooth plate service life is approximately doubled with the use of a swan-type swing jaw. Power consumption has been reduced by 20%. Features long service life and low cost. ・Designed to operate with low raw ore input, enabling supply by direct ...

More