Ore Dressing Process For Copper

Discussion on the Innovation of Copper Ore Dressing

3 天之前 01 Traditional copper ore dressing methods and existing problems. 1. Gravity separation method. Gravity separation method mainly achieves separation through the difference in specific gravity between copper ore and

More

Copper Ore Processing Plants, Flow And Equipment

6 天之前 Copper ore Process. Copper ore is divided into sulfide ore, oxide ore and mixed ore according to its oxidation rate. The main technological process of copper ore is flotation. For refractory mixed copper ore and refractory oxide

More

CN104475227A - Ore-dressing process for extracting copper and

The invention provides an ore-dressing process for extracting copper and silver. The ore-dressing process comprises the following steps: (A) grinding raw ores, and grading the...

More

CN114029156A - Green ore dressing process for copper, lead,

The invention discloses a green beneficiation process for multi-metal complex sulfide ores such as copper, lead, zinc, gold, silver and the like, which comprises the following steps: s1,...

More

Key Techniques and Methods for Enhancing Copper

2024年7月10日 Improving the efficiency of copper flotation is an important issue in the copper ore dressing process. By reasonably selecting flotation processes, controlling grinding fineness, optimizing the dosage of reagents,

More

Introduction of Copper Ore Dressing Process - Xinhai

2018年5月2日 Current copper ore dressing process includes following stages: firstly, crush the raw ore to a certain size with crushing and grinding equipment, then useful minerals

More

Copper Processing Plant, Equipment - JXSC Machinery

JXSC supports customized copper processing plant and equipment, fully suitable for separating copper oxide ore (azurite, cuprite and malachite); copper sulfide ore (chalcopyrite, bornite and chalcocite) and natural copper.

More

These Copper Oxide Ore Beneficiation Methods Greatly Recovery

2024年10月18日 30TPH Copper Oxide Beneficiation Methods. This setup is a 30 tph rock copper oxide ore process plant.It is configured with a hopper , feeder chute , hammer crusher , conveyors ,fine ore bin, Electromagnetic vibrating feeder ,ball mill , hydrocyclone , slurry pump , spiral chute , shaking table and magnetic separator .

More

ore dressing process for copper - Sabo Mining Machinery

Copper Ore Dressing Process Xinhai. WebMar 14, 2018 Copper ore refers to the mineral aggregate with a certain content of copper ore and can be recycled at the present stage. In general, copper ore is occurred in ore inside as sulfide, and associated with a certain amount of lead and zinc ore.

More

Silicate Copper Ore Dressing Process

2024年2月19日 A certain molybdenum-containing high-sulfur fine-grained silicate copper ore with a copper content of 0.42%, molybdenum content of 0.007%, and sulfur content of 11.87%. The main target metals are copper and molybdenum, with copper mainly present in chalcopyrite, bornite, and azurite, and the distribution rate of copper in secondary copper sulfide is 37.65%.

More

Introduction of Copper Ore Dressing Process - LinkedIn

2018年5月2日 Current copper ore dressing process includes following stages: firstly, crush the raw ore to a certain size with crushing and grinding equipment, then useful minerals realize full monomer ...

More

Zambia’s Copper Oxide Ore Dressing – Case Study - Dasen Mining

2024年5月21日 Among these, copper primarily existed in the form of copper oxide, adding complexity to the copper ore dressing process. Facing the intricate ore dressing conditions, the Dasen Mining team, leveraging their rich experience and professional expertise, conducted on-site exploration and analysis, and suggested targeted optimization solutions:

More

CN104475227B - Ore-dressing process for extracting copper and

The invention provides an ore-dressing process for extracting copper and silver. The ore-dressing process comprises the following steps: (A) grinding raw ores, and grading the ground ores to obtain ore pulp; (B) carrying out rough concentration on the obtained ore pulp in the step (A) to obtain first rough concentrate and first coarse slag; (C) carrying out concentration on the

More

Summary of Copper-Zinc Ore Dressing and Separation Technology

2024年7月2日 03 Research status of copper-zinc ore separation process. As the ore dressing process becomes more mature, the copper-zinc sulfide ore separation process has also been continuously developed, making the copper-zinc sulfide ore separation technology more mature, and various new processes and technologies continue to emerge, but the overall ...

More

Copper Introduction And Ore Crushing - JXSC Mineral

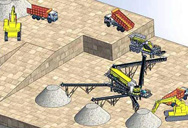

2024年6月13日 The third stage: ore dressing – mixed flotation process. The copper ore powder that meets the requirements is fed into the flotation machine for mixed flotation. The copper ore powder after flotation is fed into the dryer for drying, and finally, copper concentrate is obtained. Copper Ore Crushing Equipment

More

Ore Dressing Nickel Ore Dressing Proces

ore dressing process for copper . Copper Ore Dressing Reqired process crusher mining Copper Ore Dressing Reqired 38 Views The Zenith is the professional mining equipments manufacturer in Read More High Efficiency Josephinite Ore Magnetic . Get Price. which process is known as dressing of gold ore.

More

4 Things to Make Your Copper Ore Processing

2023年2月15日 Generally, the steps of copper ore dressing process contain 3 parts: 1 Crushing and grinding: making the copper ore rock into smaller size by using crusher and ball mill. 2 Separating: choose the copper material from

More

(PDF) A Method of Ore Blending Based on the Quality

2021年5月31日 In the production process, the ore dressing index can be used to predict the. ... Application and risk analysis at copper. deposit. Min. T echnol. 2013, 116, 109–118. [CrossRef] 8.

More

Copper Processing Plant, Equipment - JXSC Machinery

Copper ore beneficiation is a process to extract copper from raw ores. Commonly used copper ore beneficiation process include gravity separation, flotation process, and magnetic separation. Gravity separation: The gravity

More

Iron ore mining and dressing - tec-science

2018年6月21日 Before the iron ores can be fed to the ironworks, they must first be mined (ore extraction) and specially processed for the blast furnace process (ore processing). These process steps are described in more detail in the following sections. Figure: Schematic overview of an ironworks Iron ore extraction

More

LECTURE NOTES ON Mineral Processing. (3rd Semester

So mineral dressing or ore dressing is commonly regarded as processing of raw ores to yield marketable products by such physical means those do not destroy the physical and chemical identity of the ore. Economic Justification of Mineral Dressing: 1. To purify and upgrade the ore:

More

POTENTIAL ENHANCEMENT OF COMPREHENSIVE COPPER–MOLYBDENUM ORE DRESSING ...

The copper concentrate has the following phase composition, % (relative): 1.48 oxi dized; 25.35 secondary; 70.28 primary; 2.89 gray copper ore; 100 total. The comparison of data from Tables 2 and 3 yields that the incremental content of copper in the copper concentrate is achieved owing to primary copper minerals. Molybdenum concentrate.

More

Mineral Processing Plant Beneficiation Solutions - JXSC

Ore processing is the process of separating valuable minerals from its ores by ore beneficiation equipment. Mineral processing plant is recovers or extracts minerals through a range of ore dressing solutions, including washing, crushing, grinding, gravity concentration, flotation magnetic separation, electrostatic separation and more. JXSC provide full mining process

More

Copper Mining Processing: Everything You Need to Know

2014年7月17日 The laborious task of mining copper ore by hand made obtaining large quantities for production difficult. During the Industrial Revolution, coal- and steam-powered machinery paved the way for a considerable increase in copper production, with mines smelting between 200 and 300 tons of copper ore per week.

More

The Processing of Copper Ore Beneficiation - JXSC Machinery

2024年10月18日 In the development and utilization of copper resources, the grading operation of the copper ore beneficiation plant is also an important production link in the separation of copper ore. As the difficulty of copper mining and sorting increases, the requirements for screening efficiency and classification efficiency are getting higher and higher. Therefore,

More

Cyanide Leaching of Copper-Gold-Silver Ores - ResearchGate

2013年7月11日 Final considerations about the cyanide process for copper-gold ores are presented. ... 'Chemistry of Cyanidation', Mineral Dressing Notes No23, American Cyanamid Company, New York. Show more.

More