how to decide the size of cement plant

Concrete Batching Plant Size - Capacity, Types and

2023年1月18日 The size of a concrete batching plant determines the capacity of the machine. The bigger the capacity, the bigger will be the size of the plant. Concrete plant capacity essentially means the quantity of concrete

More

Key factors in setting up a cement plant

2020年1月3日 Setting up a cement plant is both time and capital intensive; it could take anywhere between five to seven years from concept to commissioning and an investment of around to Rs 1,800-2,000 crore for a typical integrated

More

The Cement Plant Operations Handbook - International Cement

The Cement Plant Operations Handbook is a concise, practical guide to cement manufacturing and is the standard reference used by plant operations personnel worldwide. Providing a

More

Concrete Batch Plant Scale: Optimize for Efficiency and

2024年1月23日 Deciding on the production scale of a concrete batch plant is a critical step in ensuring optimal efficiency and resource utilization in construction endeavors. Here’s a comprehensive guide to navigating through this crucial

More

Concrete Plant Standards

1996年9月1日 These Standards specify requirements for concrete plant, controls and plant mixer equipment eligible to be designated as standard by the Concrete Plant Manufacturers

More

Global Projects: Cement capacity expansion to 2025

2021年12月21日 Smaller plants are preferred by smaller regional markets and when investors enter new markets, a trend that has not changed much of late. OneStone also analysed the

More

Cement plant design under EPC contract - ESFC

Competent engineering design of a cement plant is the key to the success of an investment project. In this case, everything matters, from the correct choice of a construction site to the development of a technological scheme and equipment.

More

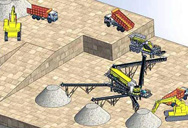

Everything To Know About Concrete Plants - Poyatos

2022年12月31日 Concrete plants can be divided into two categories: Dry mix plants, as the name implies, prepare dry recipes before sending them to a transit mixer. The aggregate, sand, and cement needed for the job are measured

More

Concrete Mix Design - Giatec Scientific Inc.

2023年6月20日 In contrast, reducing the maximal size of the coarse aggregate allows your ready mix concrete to reach higher strength at an equivalent water-cement ratio. *The Help icon available on this page proposes different

More

Dust Emission Monitoring in Cement Plant Mills: A Case Study in

2021年8月28日 The results of Soussia et al. showed that the average values of cement powder inside the cement plant were higher in January and December (up to 8.752 g/m 2 /day in January and up to 9.362 g/m 2 /day in December) and lower in the summer months (up to 5.2502 g/m 2 /day in August).

More

Construction cost of a cement plant - ESFC

The construction of a cement plant includes several typical stages, which may differ depending on the type of project and the chosen construction technology: • Planning, ... (when it comes to cement packing plants and similar smaller

More

How to Start a Cement Factory Design Construction of ...

Mini Cement Plant Hot Sale; Cement Plant 700 ~ 2000tpd; Cement Plant 2500~7000tpd; Cement Types Menu Toggle. OPC Manufacturing Plant; PPC ... investors must consider the local cement market size, cement prices, and their own investment capacity. The larger the production scale of a cement factory, the higher the construction cost and production ...

More

AIR POLLUTION CONTROL IN CEMENT INDUSTRIES IN INDIA

2016年3月10日 When cement is added to soil, it raises the pH of the soil to about 12-13 due to its hydration (Taylor 1997), which is detrimental to the ecology of soil organisms.

More

Concrete Mix Design Calculation - M20, M25, M30

Estimated water content = 186+ (3/100) x 186 = 191.6 kg /m 3 Step 4 — Selection of Cement Content Water-cement ratio = 0.5 Corrected water content = 191.6 kg /m 3 Cement content = From Table 5 of IS 456, Minimum cement Content for mild exposure condition = 300 kg/m 3 383.2 kg/m 3 > 300 kg/m 3, hence, OK.This value is to be checked for durability requirement

More

How Cement is Made - Portland Cement Association

Cement producers are constantly pursuing innovative, efficient, and environmentally responsible ways of producing high-quality cement to realize carbon neutrality across the concrete value chain by 2050. Take a look at how cement, the main ingredient in concrete, is made.

More

Cement Conveyor Belt Conveyor In Cement Plant AGICO

Cement conveyor refers to a belt conveyor in cement plant, which is necessary accessory equipment in the cement production line.. A belt conveyor is a kind of material handling equipment with strong adaptability, applied for conveying bulk density less than 1.67t / m³, it is mostly used for powder, granular, small lump materials, and bagged materials, such as sand,

More

PERFORMING A CEMENT PLANT OPERATIONS AUDIT

An operations audit should be carried out whenever important changes of a general nature are considered. Some important changes may include: a plant-wide cost reduction effort, the installation of a productivity program, thermal energy efficiency program, electrical energy efficiency program, chemistry and operations strategy, the introduction of new products,

More

How Much Does It Cost To Start A Cement Plant?

2020年5月14日 For most large cement plant manufacturers, they can provide custom solutions to cement plants, and also supply the EPC project for equipment or a cement plant. cement factory solution cement plant upgrade. Cement plant upgrade is another element we should consider, the cost of cement plant upgrade is also important for cement plant owner. As ...

More

How much does it cost to build a 1000 tpd cement plant? - LinkedIn

2023年2月17日 The overall cost to build a 1000 tpd cement plant can vary greatly depending on the size and layout of the plant, as well as the materials and machinery used. On average, it is estimated that such ...

More

Large Cement Plant for Sale

Mini Cement Plant Hot Sale; Cement Plant 700 ~ 2000tpd; Cement Plant ... material preparation in the dry process of cement manufacturing is to reduce large-sized raw materials to the proper size and mix them into ... maintenance

More

The Global Cement Report - Online Database of Cement Plants

This resource contains listings of over 2666 facilities worldwide (excluding China), and is the most up-to-date listing of cement plant information available. Basic data is available free of charge. For full access to the database, purchase The Global Cement Report™, 15th Edition.

More

Cement Plant Cement Manufacturing Plant EPC Project

AGICO Cement is a cement plant manufacturer supplies cement manufacturing plants, EPC project for cement plant, one-stop service and factory direct. Welcome to contact! Skip to content +86 13683722138. info@cement-plants. about. blog. contact. EN ES. Menu. Menu. Home; ... For spare parts: size and dimensions, material and weight, ...

More

Concrete Batching Plant Size - Capacity, Types and Advantages

2023年1月18日 • Mobile Concrete Plant type – 20 to 60 m3/hr. • Stationary type Concrete Plant – 30 to 200 m3/hr. Types Of Concrete Plant – Stationary, Mobile and Portable. The smallest size of concrete batching plant supplied and exported by Atlas can produce approximately 8-9 m3 of concrete per hour. This is essentially a mini concrete batching plant.

More

Oil Well Cement Production How To Make Oil Well Cement?

AGICO CEMENT supply cement plant for oil well cement production, and also provide cement plant equipment for manufacturing other special cement. FREE Quotation now! Skip to content +86 13683722138. info@cement-plants. about. blog. contact. EN ES. Menu. Menu. ... For spare parts: size and dimensions, material and weight, ...

More

How To Calculate The Quantity Of Cement To Be Used In

2018年4月26日 Understanding the quantity of cement to be used in stabilization is a key economic factor to be considered during stabilization process. THE PURPOSES OF CEMENT STABILIZATION. To increase the density of sub base material and thus lead to fewer voids.

More

How AI is helping cement plant operators reduce energy

size of a process engineering function with additional Chemical Engineers – they result from machine learning algorithms powered by powerful computers working through the massive plant datasets, finding optimisations each time that will work best for your daily or hourly operating parameters.1,2 Delta Zero can enable cement plant

More

Cement plant design under EPC contract - ESFC Investment Group

Choosing the optimal plant layout early in the engineering design of a cement plant is critical to ensuring the efficiency, safety and sustainability of the facility in the future. The project must take into account a whole range of factors, ranging from the technology chosen, the raw materials and equipment used, to the expected productivity and operating time (usually about 20 hours per

More

Download The Cement Plant Operations Handbook by Philip A.

Description. The Cement Plant Operations Handbook, 7th edition, 2019, International Cement Review. Publicity removed, grey....

More