what is the metal ore process

Mineral processing - Wikipedia

Before the advent of heavy machinery, raw ore was broken up using hammers wielded by hand, a process called "spalling". Eventually, mechanical means were found to achieve this. For instance, stamp mills were being used in central Asia in the vicinity of Samarkand as early as 973. There is evidence the process was in use in Persia in the early medieval period. By the 11th century, stamp mi

More

Steelmaking - Wikipedia

Modern steelmaking processes can be divided into three steps: primary, secondary and tertiary. Primary steelmaking involves smelting iron into steel. Secondary steelmaking involves adding or removing other elements such as alloying agents and dissolved gases. Tertiary steelmaking involves casting into sheets, rolls or oth

More

The stages of mining: 5 lifecycle processes explained - Opens

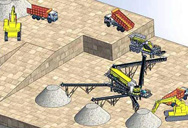

Ore is natural rock that contains valuable minerals, typically metals and is extracted from the earth through mining and extracting the valuable metals or minerals. The grade of ore refers

More

Iron Ore Processing: From Extraction to Manufacturing

2024年4月26日 Iron ore processing is a complex and vital process that transforms raw iron ore into usable steel. From exploration and extraction to grinding, beneficiation, and ironmaking, each stage plays a crucial role in

More

Introduction to Mineral Processing or Beneficiation

Ore is a term used to describe an aggregate of minerals from which a valuable constituent, especially a metal, can be profitably mined and extracted. Most rock deposits contain metals or minerals, but when the concentration of

More

Iron processing Definition, History, Steps, Uses,

Iron processing, use of a smelting process to turn the ore into a form from which products can be fashioned. Included in this article also is a discussion of the mining of iron and of its preparation for smelting. Iron (Fe) is a relatively

More

Extractive metallurgy - Wikipedia

Extractive metallurgy is a branch of metallurgical engineering wherein process and methods of extraction of metals from their natural mineral deposits are studied. The field is a materials

More

Understanding the Steel Making Process: A Flow

2024年3月20日 The steel making process starts with the melting of iron ore in a blast furnace, where impurities are removed and carbon is added. Secondary steelmaking involves refining the composition by adding or removing elements

More

Making steel - ArcelorMittal

Steel is made from iron ore, a compound of iron, oxygen and other minerals that occurs in nature. The raw materials for steelmaking are mined and then transformed into steel using two different processes: the blast furnace/basic

More

Everything about Cores in Metal Casting Process!

What is Core in Metal Casting? Core is a pre-prepared shape of the mould. It is used to provide internal cavities, recesses, ... Core material should generate minimum gases, while subjecting to molten metal in casting process. 7. Good

More

What is Smelting - Difference, Process, And Uses

2023年11月30日 Metal smelting is a process that has been around for thousands of years, and it has played a vital role in human civilization. It is the process of extracting metal from its ore. This process has allowed humans

More

Smelting: Types, Process, Uses, Challenge, Effect

2023年9月20日 Challenges of a smelting process. This process can be a difficult technique. First off, because searching for ore is challenging, there is no assurance that you will smelt the desired metal. The entire process of

More

Metallurgy - Definition, Principles Examples - BYJU'S

The following are the various steps in the metal extraction or metallurgical process: Crushing and grinding the ore. The concentration of ore, is also known as ore enrichment. Metal extraction from concentrated ore. Impure metals are refined or purified. Copper Flash Smelting Process. Principles of Metallurgy:

More

Metal Drawing Process - Principle, Classification Applications.

2023年8月10日 The metal drawing process is a fundamental manufacturing technique that transforms metal materials into desired shapes and structures through the application of force. Widely used in various industries, such as automotive, aerospace, and construction, metal forming encompasses a diverse range of methods, including bending, stamping, rolling,

More

What is Metal Core PCB, Construction, Types Applications

2021年5月12日 Hello, friends welcome to the new Tutorial. In this post, we will have a learn about What is Metal Core PCB. PcoverrCB is a printed circuit board that employed in different projects and has many types according to uses and configuration.Metalcore PCB is such type of PCB board that consists of base material created with the use of the metallic substance.

More

Mineral processing Metallurgy, Crushing Grinding Britannica

Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue. It is the first process that most ores undergo after mining in order to provide a more concentrated

More

What is Powder metallurgy Powder metallurgy types application

2022年11月25日 Forging is a crucial metal-forming process. The starting work in powder forging is a powder metallurgy part pre-formed to the proper size by pressing and sintering. The benefits of this approach include densification of the PM part, lower tooling costs, and fewer forging “hits” (and thus a higher production rate) because the starting work part is pre-formed.

More

Metal Cored Wire Welding – Benefits And Applications

2022年8月4日 Metal-cored wire also produces a broad, cone-shaped arc and a wider penetration profile compared to solid wires, for example. This wider arc shape results from the current traveling through the outside of the metal-cored wire’s metal sheath during the welding process (generally, a spray transfer mode).

More

Aluminum processing - Ores, Refining, Alloying Britannica

Aluminum processing - Ores, Refining, Alloying: Aluminum is the third most abundant element on Earth’s surface. Only oxygen and silicon are more common. Earth’s crust to a depth of 16 km (10 miles) contains 8 percent aluminum. Aluminum has a strong tendency to combine with other common elements and so rarely occurs in nature in the metallic form.

More

Metal Cored Welding: Why It’s So Popular

2021年9月28日 Metal core wire also helps to reduce welding defects such as porosity, lack of fusion, and undercut. The picture above shows a good weld made with metal-cored wire. 138 Welding Process. Metal Core Arc Welding

More

12.3: Metals and Ores - Chemistry LibreTexts

Metal ores contain sufficient minerals with important elements including metals that can be economically extracted from the rock. The ores must be processed to extract the metals of interest from the waste rock and from the ore minerals.

More

15 Different Types of Casting Process Explained [with

2023年5月16日 The casting process is the oldest and most popular method of manufacturing means of designing the desired shapes. It is the first step in manufacturing most products. Casting is made from any type of metal that

More

Annealing (materials science) - Wikipedia

In metallurgy and materials science, annealing is a heat treatment that alters the physical and sometimes chemical properties of a material to increase its ductility and reduce its hardness, making it more workable.It involves heating a material above its recrystallization temperature, maintaining a suitable temperature for an appropriate amount of time and then cooling.

More

Everything about Cores in Metal Casting Process! - CraftMach

What is Core in Metal Casting? Core is a pre-prepared shape of the mould. It is used to provide internal cavities, recesses, ... Core material should generate minimum gases, while subjecting to molten metal in casting process. 7. Good Surface Finish: Core surface should be smooth enough to provide good surface finish of the casting. 8.

More

Ore Definition, Types Examples - Lesson - Study

2023年11月21日 Once ore is mined, it is then processed and the valuable materials it contains are refined for use. The refining process usually involves one of two methods.

More

Mineral processing Metallurgy, Crushing Grinding Britannica

Mineral processing, art of treating crude ores and mineral products in order to separate the valuable minerals from the waste rock, or gangue. It is the first process that most ores undergo after mining in order to provide a more concentrated

More

Extraction of Metals from Ores – Different Processes Involved

This is generally used when the metal ore is much heavier than the impurities. Magnetic Separation: The name of the concentration process is enough to explain. This technique is used to separate the ferromagnetic metal ore from the impurities after pulverizing. The ground ore particles are carried on a conveyor belt with two wheels.

More

The Complete Guide to Metal Plating Process and Types

Metal plating, often referred to as plating metal or metal finishing, involves coating a substrate with a thin layer of metal. In the ever-evolving world of manufacturing, metal plating has established its importance as a crucial process enhancing the life, functionality, and appearance of various products.

More

What is Metal forming? Metal Forming types Applications

2024年5月30日 Complex Process Control – Achieving consistent quality in metal forming can be challenging and requires precise control of process parameters such as temperature, force, and speed. Residual Stresses – Forming processes can introduce residual stresses into the metal, which may affect its performance and require additional processes like stress relieving.

More