primary crusher gyratory crusher table

Mining crushers SuperiorTM MKIII Primary Gyratory - Metso

Metso Outotec’s line of Superior™ Primary Gyratory crushers are designed to meet the demand for high efficiency and high capacity mining installations. Superior™ MKIII is the first high

More

Metso SUPERIOR® gyratory crushers - Metso

Metso SUPERIOR gyratory crushers are built to help you meet the challenges of highcapacity primary crushing. With thousands of units operating in mines and quarries around the world, Metso has the experience and capabilities to

More

Industrial Solutions Gyratory crushers - ThyssenKrupp

KB 63-89 for iron ore. Capacity: 6,200 t/h. When it comes to crushing blasted hard rock in ore and natural stone mining, the efficiency of thyssenkrupp gyratory crushers in primary

More

Superior™ MKIII 54-75 primary gyratory crusher - Metso

Superior™ MKIII 54-75 primary gyratory crusher is a perfect fit for mid-sized operations. Contact our sales experts. Higher throughput. Increased speed, installed power and mechanical improvements. Reduced downtime. New set

More

Gyratory and Cone Crusher - ScienceDirect

2016年1月1日 Primary crushers are solidly built to receive large lumps of rock directly from the mines and designed for large tonnage throughputs. Basically, gyratory crushers consist of a

More

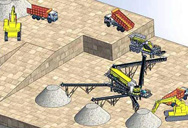

Primary Crushing Stations I FLSmidth

Offering the highest throughput rates (up to 14,000 tph), our direct-fed Primary Crushing Plants with Gyratory Crushers provide proven, standardised in-pit crushing that can be adapted to any application.

More

MASTER YOUR OUTPUT CRUSHER SELECTION QUICK GUIDE

A crusher is a major investment, so it’s essential to select one with the potential to meet your needs into the future. This guide covers a few of the key points to consider before making a

More

Gyratory Crusher - an overview ScienceDirect Topics

Primary crushers are solidly built to receive large lumps of rock directly from the mines and designed for large tonnage throughputs. Basically, gyratory crushers consist of a fixed solid

More

Crushing Products Size and Shape -What to Expect

2016年2月26日 Primary Crusher Product. ... Suppose that a tentative selection of a 3.5″ open- side discharge setting has been made for a standard gyratory primary crusher to be used for crushing quarry-run limestone. ... Inasmuch as the table of crusher settings versus equivalent product percentages is based on square openings, ...

More

Used Gyratory-crushers For Sale - A.M. King

UNUSED FLSMIDTH (Fuller-Traylor) 60" x 89" NT Gyratory Crusher with 600 kW (816 HP) Motor. Manufacturer: FLSMIDTH. Location: Asia Pacific. Inventory ID: 3C-GM01. View Details. Size: 60" x 89 ... NORDBERG 42 x 86 XHD Primary Gyratory Crusher with 600 HP (450 kW), 60 hz drive motor. Manufacturer: METSO OUTOTEC. Location: Europe. Inventory ID: 3C ...

More

Crusher parts – Vishwakarma Industries

Primary Gyratory PARTS; HSI Crusher Parts; VSI Crusher Parts; Crusher Re-Build Facility Menu Toggle. ... we bring unparalleled expertise to the table. ... Screen Spare Parts. Primary Gyratory Parts. HSI Crusher Parts. VSI Crusher Parts. About Us . Established in 1981, Vishwakarma Industries has been a pioneer in providing comprehensive ...

More

Jaw Gyratory Crusher Pro - FLSmidth

Shaking Table. Back. Mercury Retort. Back. Gold Refinery Systems. Back. Slurry Pumps. Dorrco™ Diaphragm Pumps Gorator Pump KREBS® gravelMAX™ slurry and dredge pump KREBS ... A mining primary jaw gyratory crusher for large, coarse materials .

More

Gyratory Crusher Hazemag North America

A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant. Gyratory crushers are designated in size either by the gape and mantle diameter or by the size of the receiving opening. Gyratory crushers can be used for primary or secondary crushing.

More

Jenis - Jenis Crusher dan cara kerjanya Antek Shared - Blogger

Sebuah crusher cone operasinya mirip dengan crusher gyratory, dengan kecuraman kurang dalam ruang menghancurkan dan lebih dari zona paralel antara zona menghancurkan. Sebuah crusher cone istirahat batuan dengan meremas batu antara spindle eksentrik berkisar, yang ditutupi oleh mantel tahan aus, dan hopper cekung melampirkan, ditutupi oleh cekung mangan

More

Choosing the right primary crusher for limestone crushing - Baichy

2024年7月10日 It including gyratory crusher, jaw crusher, and impact crusher. Primary crushers reduce large limestone material, such as rocks and ore lumps, into smaller sizes for further processing downstream. Home About us

More

Makalah pengolahan mineral crushing PDF - SlideShare

2015年6月26日 2.2.2 Gyratory Crusher Gyratory Crusher juga merupakan alat yang di gunakan pada tahapan primary crushing dan merupakan hasil pengembangan alat crushing untuk mendapatkan kapasitas yang besar. Gambar 2.2 Gyratory Crusher Karakteristik penting pada Gyratory Crusher yaitu : a. Ukuran partikel yang menurun b.

More

Primary Crushing Equipment: Jaw Crusher vs. Gyratory Crusher

2024年6月7日 The content provides a comprehensive overview of the primary crushing process in the mining industry. Skip to content. 31 Oct 2024. ... Primary Crushing Equipment: Jaw Crusher vs. Gyratory Crusher. AllMinings 5 months ago 2 months ago 0 14 mins. Subscribe to continue reading.

More

Gyratory Crusher vs. Cone Crusher: What's the Difference?

2023年2月23日 A gyratory crusher has a mantle that rotates within a concave bowl, while a cone crusher has a mantle that rotates within a bowl-shaped concave. This design allows for a larger feed size and a higher capacity for both types of crushers, but gyratory crushers are typically designed for high-capacity crushing whereas cone crushers are intended for smaller

More

Crusher - an overview ScienceDirect Topics

They come in many varieties, and a summary of different crusher types is provided in Table 8.1. Table 8.1. Comparison of different crusher types. Crusher type Typical process stage Maximum feed size (mm) Typical maximum product size (mm) Typical capacities (t/h) Gyratory crusher: Primary: 1500: 200–300: 1200-over 5000: Jaw crusher: Primary ...

More

Superior™ MKIII 54-75 primary gyratory crusher

During the development of the Superior™ MKIII 54-75 primary gyratory crusher, there have been tests conducted extensively at different mining sites in the field. The new features and upgrades have proven to be very useful,

More

AMIT 135: Lesson 5 Crushing – Mining Mill Operator

The ratio of reduction through a primary crusher can be up to about 8:1. Feed: ROM up to 1.5 m; Product: -300mm (for transport) to -200mm (for SAG mill) Feed Rate: 160 to 13,000 tph; The family of primary crushers include: Gyratory

More

Industrial Solutions Gyratory crushers - ThyssenKrupp

ing chamber below. Jaw gyratory crushers can handle much bigger chunks of material than comparable gyratory crushers of the same mantle diameter. Jaw gyratory crushers feature a higher crushing ratio and less tendency to become clogged in the feed zone as a result of bridging Jaw gyratory crusher Weights 1) Type Feed opening Mantle diameter ...

More

MASTER YOUR OUTPUT CRUSHER SELECTION QUICK GUIDE

The first considerations are at what point in the process the crusher will be used, the type of material, and the output required. Use the table below as a guide. Primary Gyratory Crusher B G G Primary Jaw Crusher G B G Primary HSI Impact Crushers P P B Secondary Cone Crushers S-type B G Secondary HSI

More

Gyratory Crusher (Gyratory Crushers Explained) - saVRee

Crusher Types There are three common crushers used at mining and processing plants: Gyratory Crushers; Jaw Crushers; Cone Crushers; Typically, the initial crushing stage is completed using either gyratory crushers or jaw crushers. It is often the case that there will be only one crusher installed, and this will be referred to as the ‘Primary ...

More

Crusher Close Side Settings - 911Metallurgist

2016年1月18日 Crusher Close Side Settings. When it is necessary, or desirable, to operate a gyratory crusher at discharge settings below the minimum standard, the safe procedure is to fit the machine with a reduced throw eccentric. The crusher manufacturer will be able to advise the operator about these special throws for machines of his make.

More

Sandvik CG820 Primary Gyratory Crusher For Safe Crushing

Sandvik CG820i crusher is built to be robust, reliable and efficient. Connected to SAM by Sandvik, ... Our range stationary gyratory crushers Stationary gyratory crushers. CG850i Capacity (by hour) 3,800 - 8,250 mtph (4,180 - 9,075 stph) Feed opening 1,549.0 mm ...

More

The Complete Guide to Primary Crushing, Secondary Crushing,

2023年2月28日 Learn everything you need to know about primary crushing, secondary crushing, and tertiary crushing in this comprehensive guide. Discover the types of crushers used in each stage, their working principles, and the advantages and disadvantages of each process. Get answers to frequently asked questions and improve your understanding of the

More

What Is Primary, Secondary, and Tertiary Crushing? - Eagle Crusher

2020年7月10日 Primary crushing is the first stage of material reduction and can sometimes be the only stage needed to generate the desired product for a job. ... or reclaimed and process it through an impactor, jaw, or gyratory crusher to generate a range of product sizes. For many aggregate producers, ...

More